Thermal Analysis and Thermal Management Services

With the passing of time the expectation is that electronic equipment will deliver more features and higher performance whilst becoming more reliable, smaller, lighter and produced at lower cost. There has never been a greater reliance on effective thermal management.

Almost all systems we work on today require a degree of thermal analysis to verify that maximum permissible component temperatures will not be exceeded. Often thermal management in one form or another is required to improve thermal performance and provide more acceptable margins.

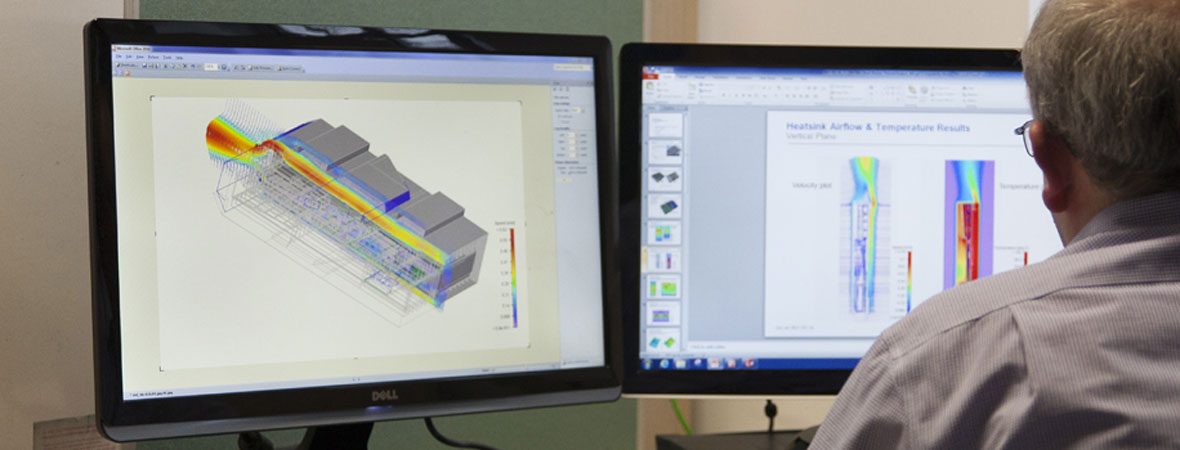

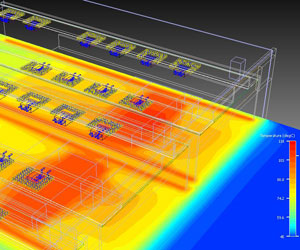

T hermal analysis and thermal management, using industry-leading CFD software such as FloTHERM and SolidWorks Flow Simulation forms an integral part of our design services and begins at concept phase. The powerful 3D computational fluid dynamics (CFD) software predicts airflow and heat transfer in and around electronic equipment, from components and boards through to complete systems and ultimately is used to predict critical temperatures such as component junction temperatures, local internal ambielt temperatures or safety-critical surface “touch” temperatures. The predictions are then compared to the maximums set by the component manufacturers and the design re-worked if the specified conditions are not met.

hermal analysis and thermal management, using industry-leading CFD software such as FloTHERM and SolidWorks Flow Simulation forms an integral part of our design services and begins at concept phase. The powerful 3D computational fluid dynamics (CFD) software predicts airflow and heat transfer in and around electronic equipment, from components and boards through to complete systems and ultimately is used to predict critical temperatures such as component junction temperatures, local internal ambielt temperatures or safety-critical surface “touch” temperatures. The predictions are then compared to the maximums set by the component manufacturers and the design re-worked if the specified conditions are not met.

We also offer thermal analysis and thermal management as standalone services, and can import geometry from many leading CAD packages to save re-modelling.

Amongst the services we provide are:

- Complete thermal analysis and thermal management of systems: architecture to implementation

- Practical cooling of electronics: conduction, natural convection, forced convection and water cooling

- Bespoke heatsink design for optimum performance

- Experience of heat pipes, vapour chambers and active cooling such as Peltier devices

- Solar gain considerations

- Design of pumping systems and bespoke impellers

- Use of multiple tools as necessary: “hand” calculations, 1-D analysis, empirical methods, Computational Fluid Dynamics (CFD)

- Fluid flow optimisations: pressure drops and system balancing

- Analysis from component, through card/module to system Level

- Transient (time domain) simulations

- Mixed flow analysis

- Consultancy on reliability, debris filtration and acoustic noise

- Performance trade-offs with EMC, reliability and cost

- Verification by experimentation / test where practicable