Reverse Engineering Services

We are able to retrospectively record the build of existing hardware and create datasets to enable it to be re-created, updated or cost reduced. Our reverse engineering services have been useful to clients who have capability to design & manufacture their own jigs and fixtures in-house, but then need to record or reproduce them accurately.

We are able to retrospectively record the build of existing hardware and create datasets to enable it to be re-created, updated or cost reduced. Our reverse engineering services have been useful to clients who have capability to design & manufacture their own jigs and fixtures in-house, but then need to record or reproduce them accurately.

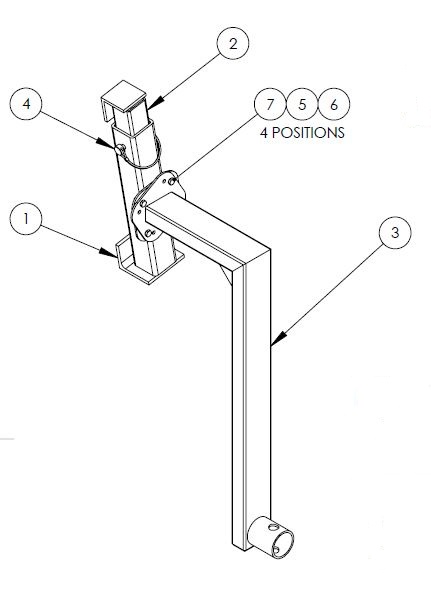

The process usually begins with a survey of an existing piece of equipment. We have found that the most efficient way to do this and the most unobtrusive to the client is to initially rough-model from photographs and to create fully-dimensioned drawings whilst in our office. Although the dimensions are bound to be incorrect they are very easily modified after comparing the measured “actuals” against the dimensions that we have on our drawing. In the case of large equipment this can be done at the client’s premises using CAD on a mobile workstation / laptop. It is then just a case of simply inspecting the parts / assemblies to the drawings we have produced, marking-up the drawings as we go.

Using this process, it would normally take possible to document a sizeable piece of equipment in just one or two site visits.

Smaller, complex components such as injection mouldings can sometimes be dealt with more effectively through the use of 3D scanning. Specialist software may then be used to convert the resulting 3D geometry into native SolidWorks features so that the 3D models are able to be edited as if they were created in SolidWorks.

Reverse Engineering of parts or assemblies that feature special materials, finishes and fits is more challenging as it requires us to gain insight as to why those special features were originally considered to be necessary. Once we deduce that a special material property or feature is necessary we utilise our knowledge of materials and their properties, temper conditions, textures, finishes and limits & fits to identify what’s required. This sometimes requires us to send samples of parts to materials experts for analysis of composition, hardness and texture measurement.