The Engineering Design Process

It is widely accepted that around 75% of the cost of a product is designed-in during the concept stage. It is also true that the cost of making a design change increases considerably as development advances and is at a peak when the tooling has been put into place, when there is inventory and when regulatory testing has been performed. It is therefore vitally important that the right selection is made when choosing the concept and at the most basic level this begins with a thorough understanding of the requirements.

Design Requirements

For us the most important stage of the engineering design process is the first one – establishing clear and unambiguous requirements with acceptance criteria. By asking the right questions we help our customers to understand and refine their priorities and requirements from the start, such as:

- how many will be made?

- what are the cost targets and how will the cost of manufacturing tooling be met?

- where and how will it be used? Who by?

- what is its intended design life? What about maintenance?

- strategy for repair: Field Replaceable Units (FRUs), Return to Base (RTB)?

- any requirements for Hot swap / Redundancy / De-rating / Fan fail?

- where is the intended market and what regulatory requirements should it conform to?

- how will it be shipped / assembled / installed / serviced / recycled?

- what do we know about the end users and their expectations? How will the product delight them?

We do much more than just ask questions; we offer the benefit of considerable design and engineering expertise to our clients to ensure that they get a fully considered design from day one. The objective is simple: to air all inputs so that the best solution can be identified as early as possible in order to save both time and money.

Concept generation & selection

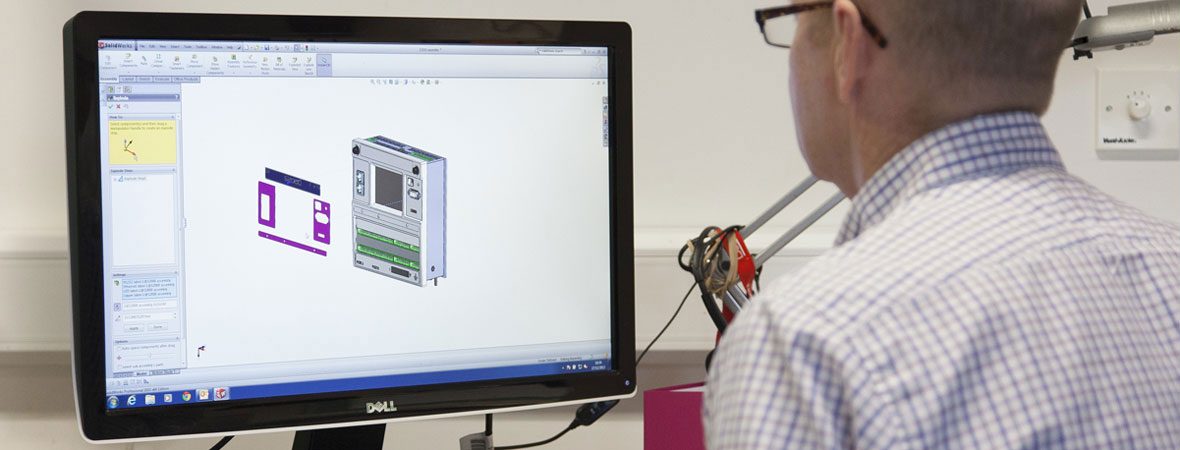

Once the design criteria have been established, we move onto the concept design stage. Often this starts as a pen and paper exercise before moving onto CAD, and usually involves consideration of several candidate ideas.

Critically, we engineer at this Concept stage using the very latest CAD, FEA and CFD design, analysis and verification tools to ensure that the concept meets all specified design criteria such structural integrity, thermal performance, mass constraints etc. This ensures that the concept is “sound” and allows us to pick a “winner” very early in the project, reducing on-going development time considerably. Our Concept Ready review is a major milestone, at what point the manufacturing process are selected and supply-chain is identified and engaged. It is at this early point in the process that the manufacturing costs, tooling costs and lead-times can be determined, thus de-risking the development programme.

Expressed visually in terms of effort applied by phase the overall process may look like this:

Detail design and documentation

Once a project advances to detail design all stakeholders will have bought-into the concept selection, so any failing post-Concept Ready can only be a failing in the detail design. The detail design stage is really circling back around the concept, ensuring that modelling of CAD geometry locks-in the design and manufacturing intent. From here on, minimal manufacturing documentation should just roll-out of the design files and provide a means of conveying finer details such as material and finish specifications, special geometric tolerancing requirements and as a means of conveying inspection criteria.

Prototype build and test

We can utilise both rapid and traditional prototyping techniques for fit, form and functional testing to validate the concept. This is a vitally important step in the process and furthermore provides our customers with a physical model that can be an invaluable aid whether it be for sales & marketing purposes, liaising with manufacturing facilities etc.

Transfer to Manufacture

Once being from the manufacturing industry we have a good appreciation of how the manufacturing world works. We want to consider preferences for tooling, manufacturing process, products structure, coding, inspection staging, requirements for datasets etc. in the concept stage so that the needs are accommodated very early on. This makes transfer to manufacture much smoother and more efficient later in the development cycle – not at all the “over-the-wall” mind-set that may have once prevailed in industry.

We are happy to recommend suitable suppliers and manufacturers from those with whom we have worked over the last 30 years, according to process requirements and target manufacturing volumes.