I have recently been visiting secondary schools to find the most suitable for my daughter, and I was delighted to see that many have a 3D printer in their Design Technology workshop. With print-to-order giveaways the machines were a great draw for prospective students and parents alike.

This is great to see, as it is an exciting new means of engaging young people with engineering…

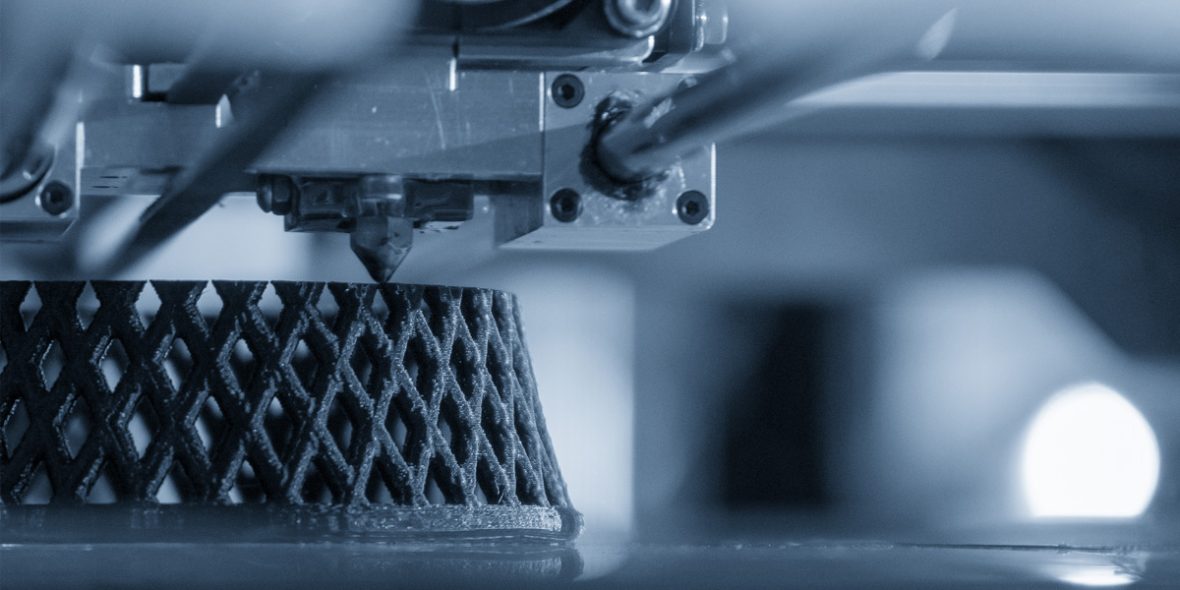

Rapid Prototyping technology is not new, of course, it’s been around since the 80’s, but it is now very much in the public domain as equipment costs come down and quality, reliability and as material choices improve. Of course the machines that are now available to the home user are not in the same league as those used by the numerous Rapid Prototyping bureaus, but they do make the technology accessible to people both inside and outside the profession.

Every RP service provider will have a cabinet full of demo pieces to show what amazing geometry can be created by Additive Manufacturing methods such as SLA, SLS and DMLS which prints a type of metal. I carry a ball-within-a-ball-within-a-ball demo piece around in my briefcase that was printed in one go – it’s a pleasing and tactile item that would have been all but impossible to make with any other manufacturing technique.

Often people ask me “but isn’t it brittle?” and I throw it as hard as I can at the wall and catch it when it bounces right back. I’ve even seen a fully working model of a reciprocating engine printed in one go, with no assembly at all. And the real world applications go way beyond making toys to delight my inner child, and include futuristic-sounding surgical tasks such as creating prosthetic body parts such as bones, facial reconstruction and scaffolding that securely holds a patients shattered bone in place while it heals. All clever stuff, and life changing for the recipients.

It is a game-changer as a means of articulating design intent at low cost and in a matter of a couple of days. It gives a designer total freedom to create “impossible” shapes and geometry with just the emailing of a file, knowing that it will be delivered in just a few days.

The unarguable disadvantages of using Rapid Prototyping techniques for manufacture are that there are limitations on the materials that can be processed and it is time-intensive, so in most cases is too slow and uneconomical for anything beyond very low volume manufacture.

In short, I am a huge fan of Rapid Prototyping technologies and they have brought a whole new world of possibilities. On the flip side, the dangers of Rapid Prototyping technologies are that they have opened up a world of impossibilities, where things are not fit for economical manufacture.

And that’s it. It laughs in the face of all the “design for manufacture” skills that have been deeply engrained in people like me who “served time” in a craft apprenticeship followed by years of professional development to equip them for a career in engineering design.

We firmly believe that manufacturability is all too often overlooked the cornerstone of good design (see our Principles of Great Design). If used inappropriately, does Rapid Prototyping risk widening the gulf between design and volume manufacture? And does the ability to make something, without optimisation for a specific volume manufacturing processes, carry the risk of creating a new breed of designers that are incapable of “real world” product design, where parts are optimised for manufacturability and cost?

Warley Design provides mechanical design, engineering and product development services to a broad range of industries. To find out more call us now on 01277 261066 or email us.